Air Cooled Chiller

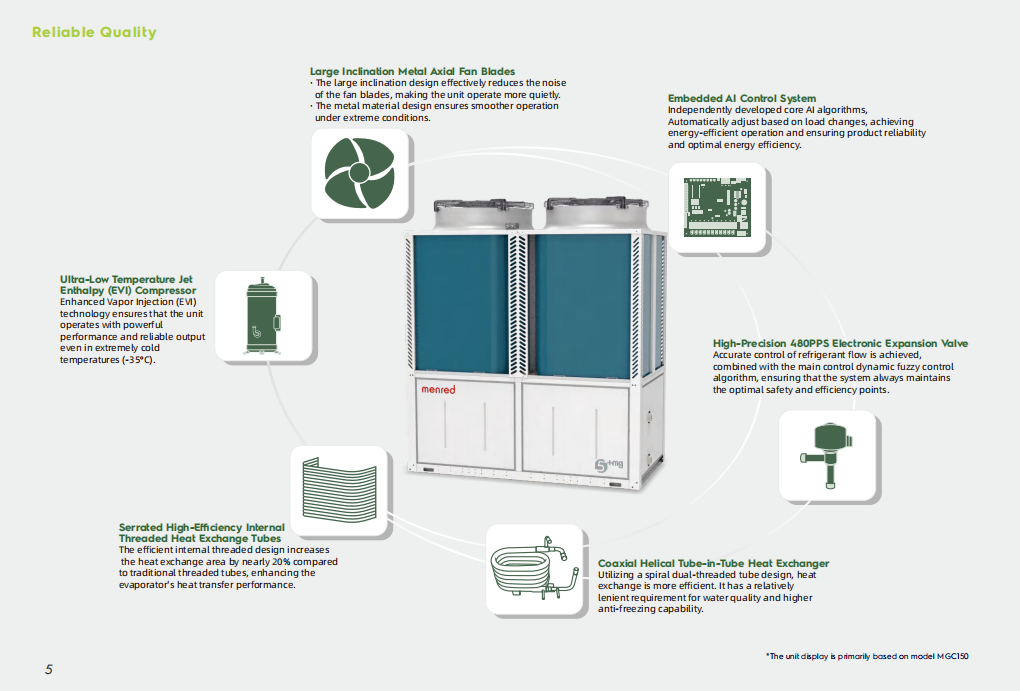

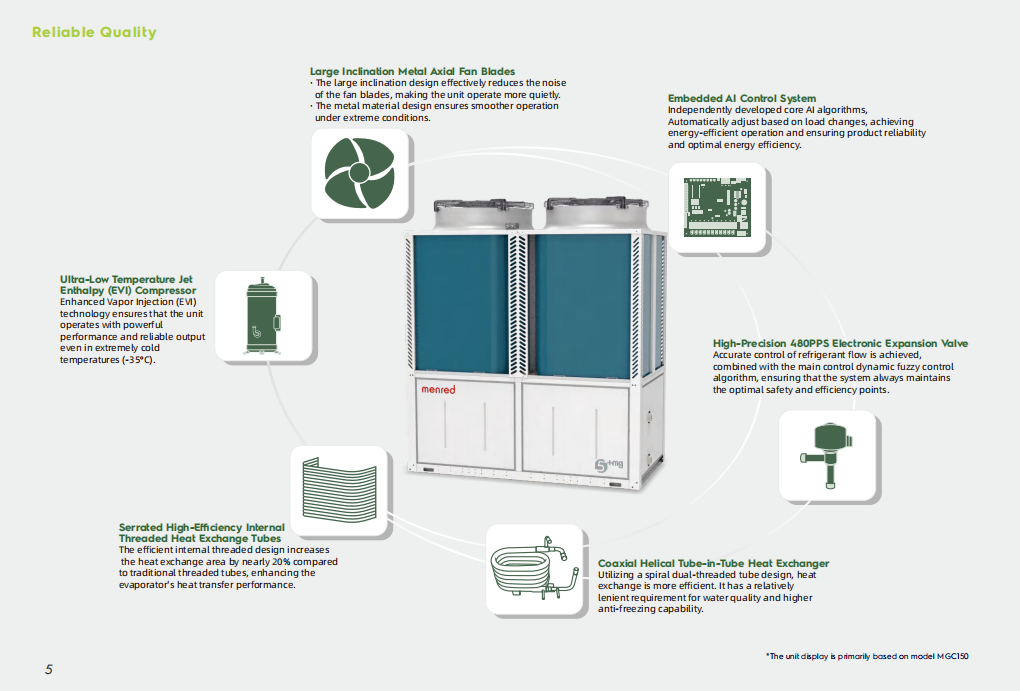

Menred Air-cooled chillers uses ambient air to remove heat from the refrigerant and cool down the process or equipment.this refrigeration systems that can be used in both commercial and industrial settings to cool fluids and dehumidify air. Air-cooled chillers are often used in hotels, commercial offices, sporting events, industrial and manufacturing plants.

It offers several advantages:

- Cost-effectiveness: Air-cooled chillers eliminate the need for complex water-cooling systems, such as cooling towers or water pumps. This reduces installation expenses and ongoing maintenance costs associated with water treatment and system operation.

- Flexibility and Space-saving: Air-cooled chillers are self-contained units, meaning they do not rely on external water sources for cooling. This makes them suitable for installations in areas where water availability is limited or where space constraints make installing a water-cooled system challenging.

- Higher Reliability: Air-cooled chillers are less prone to issues related to water quality, such as scale buildup or corrosion. They offer a reliable cooling solution that can operate even in adverse environmental conditions without compromising performance.

- Maintenance: lower maintenance costs, a prepackaged system for easier design and installation, and better performance in freezing temperature.

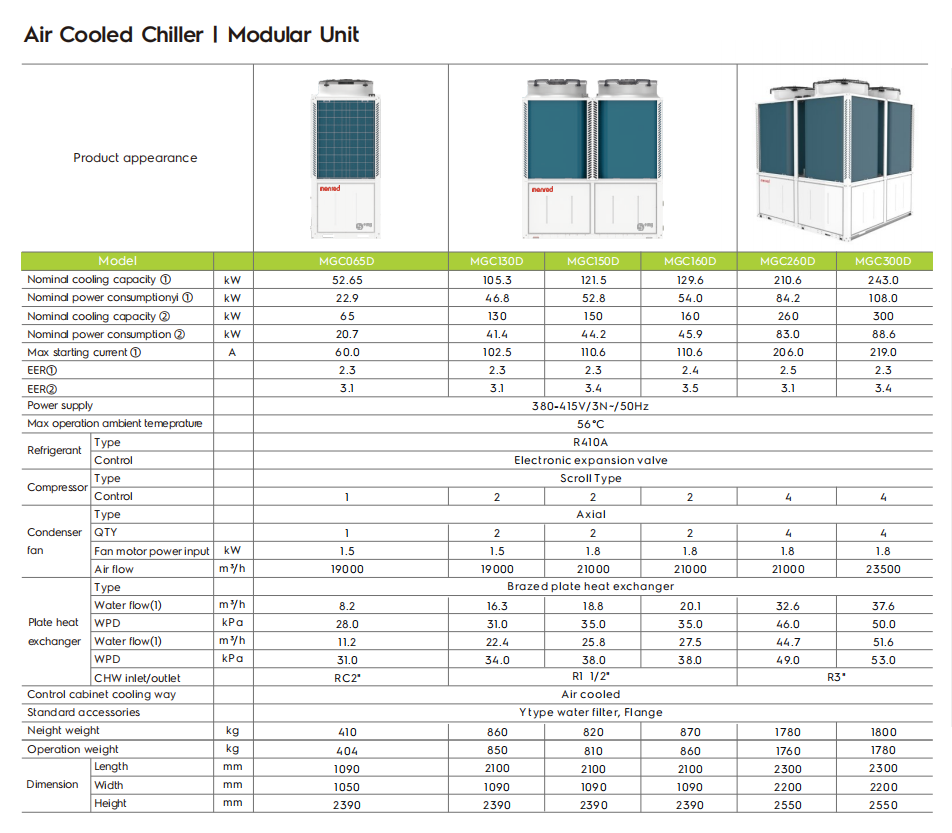

Note:

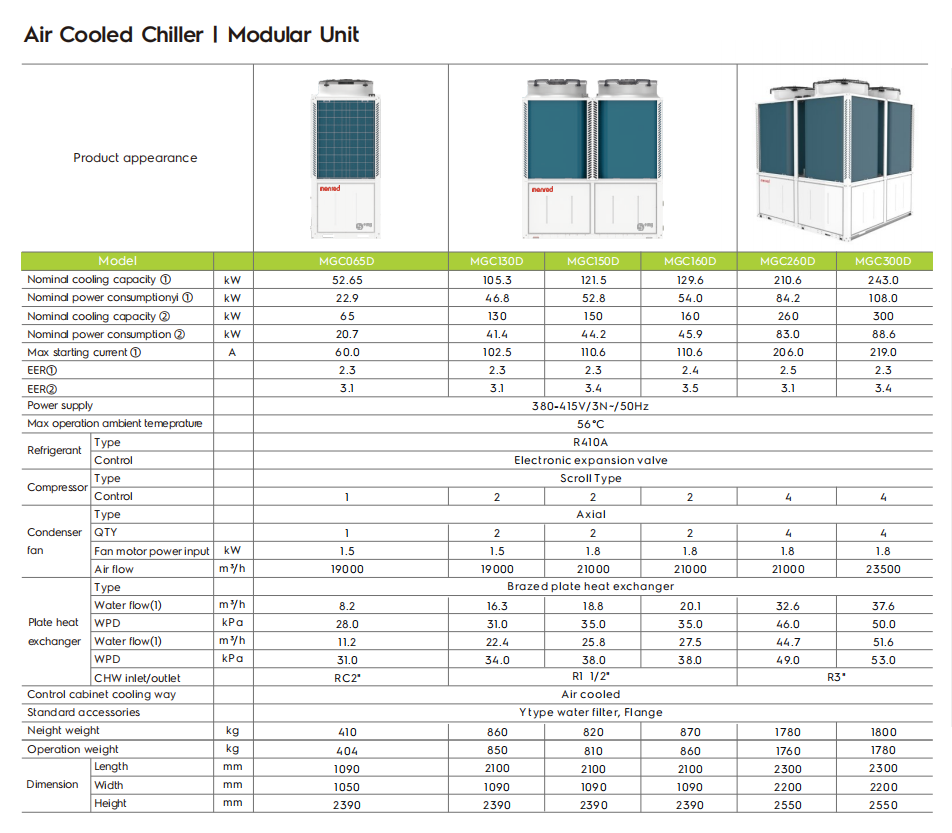

a. Nominal cooling capacity conditions: outlet water temperature 7℃, water flow rate 0.172[m3/(h·kW)], outdoor ambient temperature 35℃.

b. Rated heating capacity conditions: outlet water temperature 45℃, water flow rate 0.1548[m³/(h·kW)], outdoor ambient dry-bulb temperature 7℃, wet-bulb temperature 6℃.

c. The specifications in the table may be subject to change without notice due to changes in the manufacturer's product design.

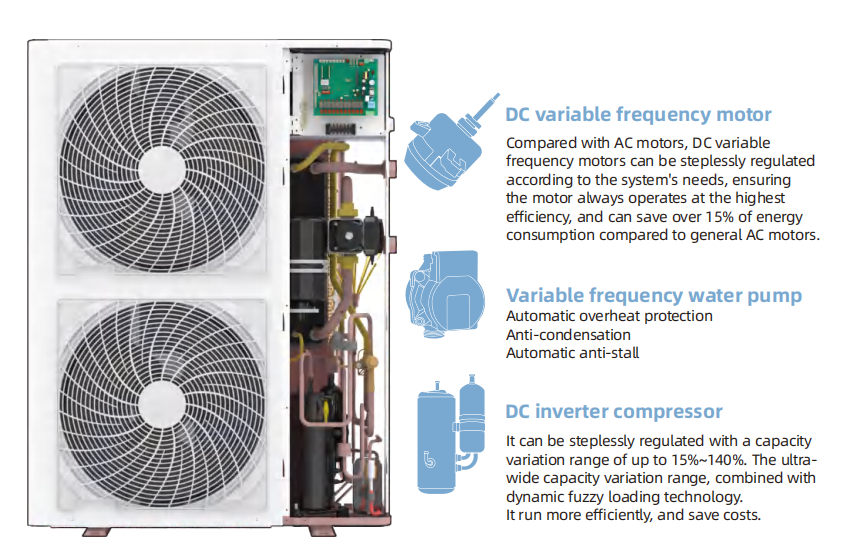

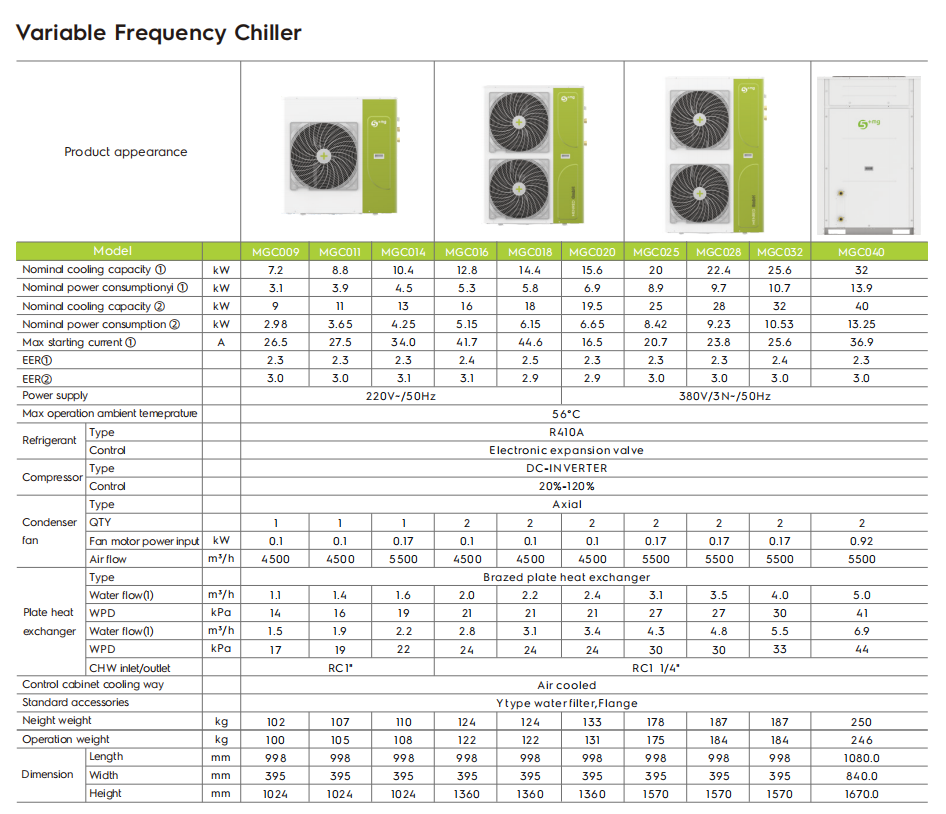

Variable frequency chiller

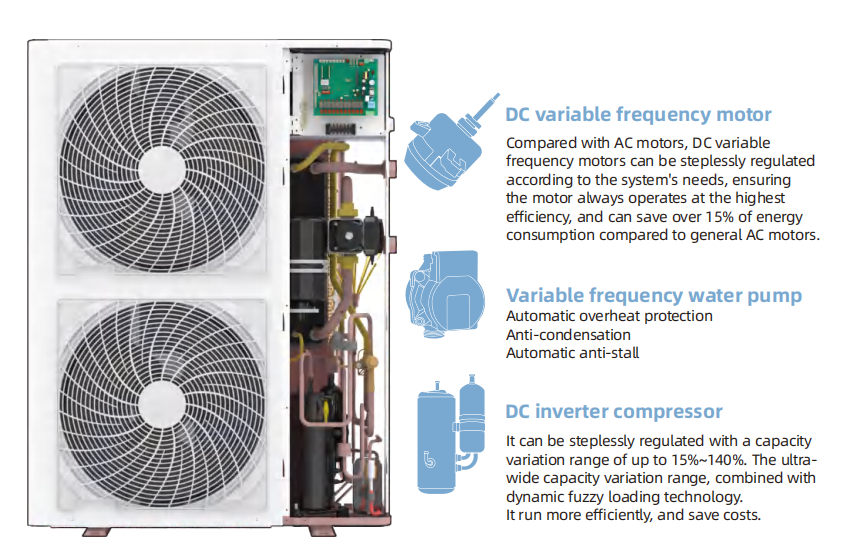

Menred variable frequency chiller, also known as a variable speed chiller, is a cooling system that can adjust its operating frequency to match the cooling load requirements. It offers several advantages:

- Energy Efficiency: The variable frequency drive technology allows the chiller to modulate its compressor speed according to the cooling demand, resulting in significant energy savings compared to fixed-speed chillers. It ensures that the chiller operates at the optimum efficiency level, reducing energy consumption and operating costs.

- Precise Temperature Control: Variable frequency chillers can accurately maintain the desired temperature by adjusting the compressor speed. This fine-tuning capability ensures the cooling system operates within a narrow temperature range, enhancing process stability and product quality.

- Reduced Mechanical Stress: By eliminating the frequent start/stop cycles associated with fixed-speed chillers, variable frequency chillers experience less mechanical stress, leading to lower maintenance requirements, increased reliability, and longer equipment lifespan.

Note:

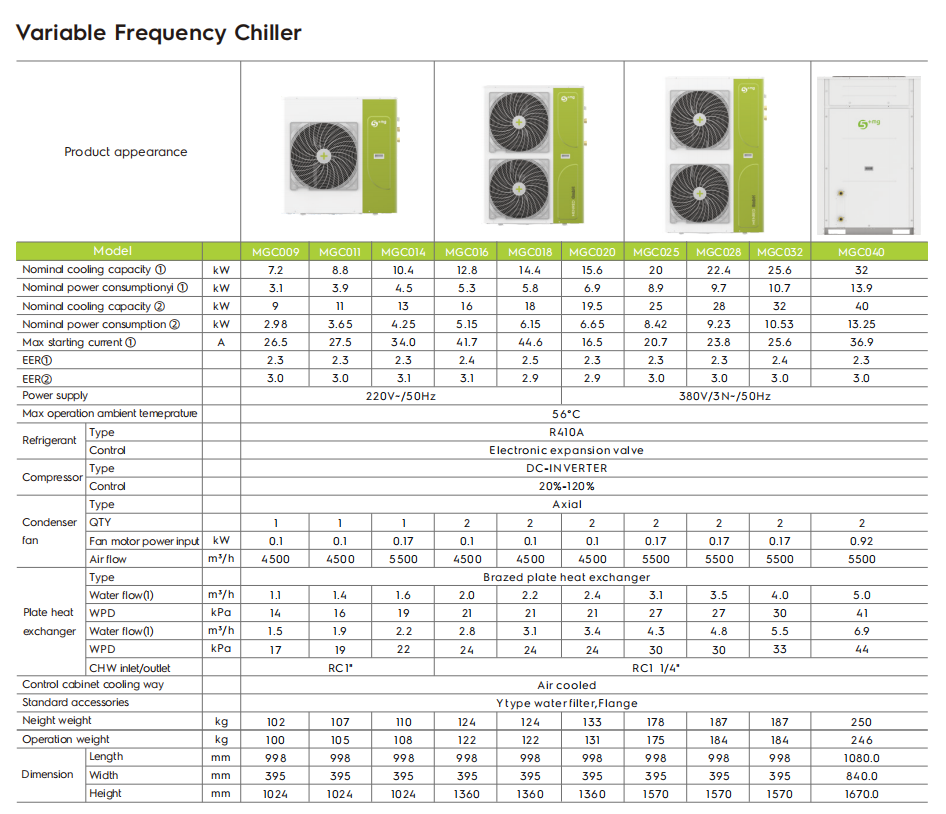

1. Nominal cooling capacity conditions: outlet water temperature 7℃, water flow rate 0.172[m3/(h·kW)], outdoor ambient temperature 35℃.

The specifications in the table may be subject to change without notice due to changes in the manufacturer's product design.