Revolutionizing Temperature Control: The Power of Thermal Actuators in Underfloor Heating Systems

views: 3078 time: 2025-03-09

views: 3078 time: 2025-03-09

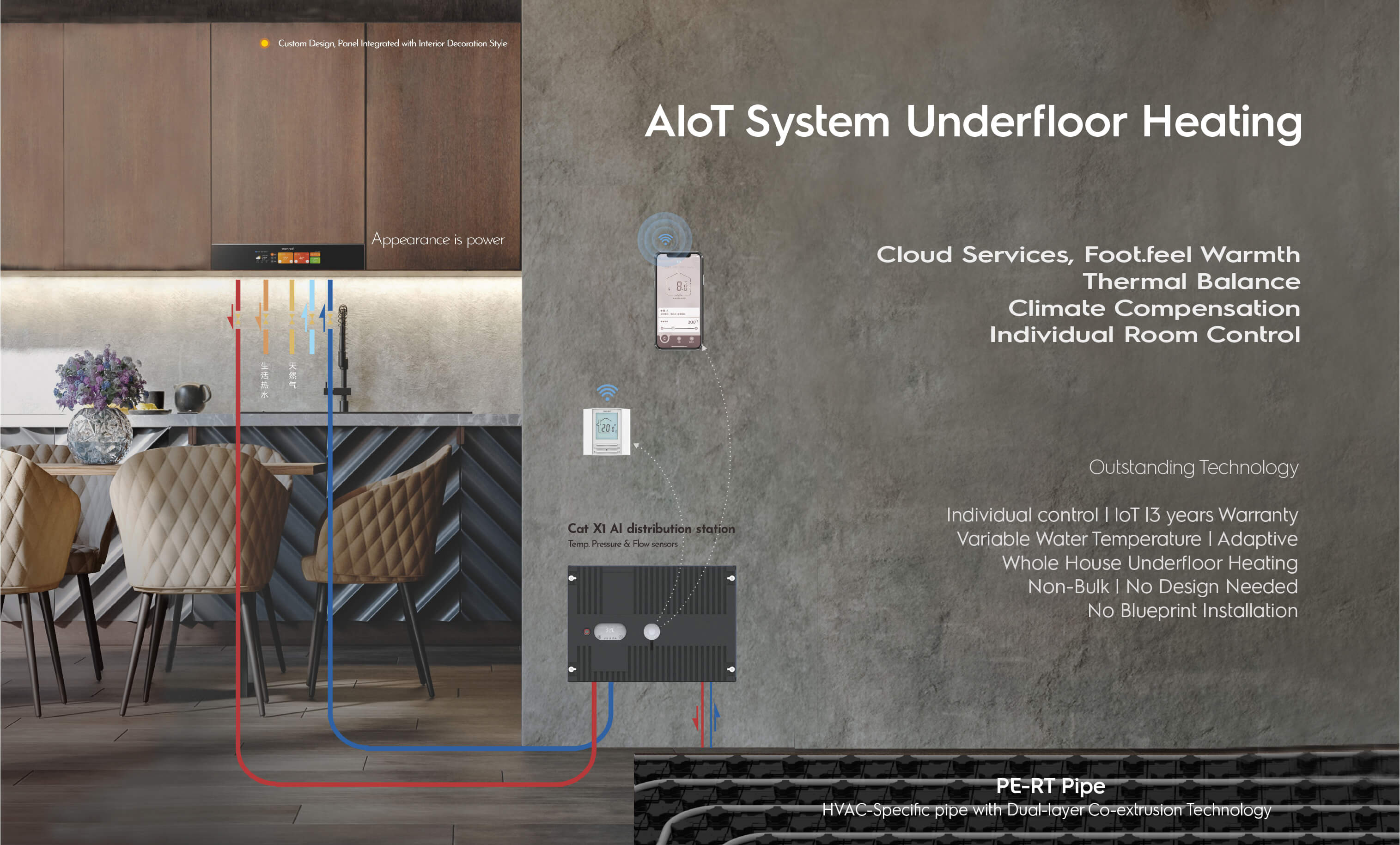

In today’s era of smart and energy-efficient homes, innovation in temperature control technology is paramount. Among the breakthrough technologies making a significant impact is the thermal actuator—a compact yet powerful device that converts thermal energy into mechanical motion. Not only does it play a critical role in applications such as HVAC systems, automotive components, and home appliances, but its integration with underfloor heating systems has also redefined comfort and energy management in residential and commercial spaces.

This article will explore the inner workings of thermal actuators, their diverse applications, and their transformative benefits for underfloor heating systems. We will also delve into key aspects under subheadings such as “What Are Thermal Actuators Used For?” and “How Does a Thermostatic Actuator Work?” to give you an in-depth understanding of the technology behind the scenes.

Understanding Thermal Actuators

Understanding Thermal ActuatorsAt its core, a thermal actuator is a device engineered to convert heat into mechanical movement. Using a wax motor mechanism, these actuators exploit the fundamental property of thermal expansion—the tendency of materials to change dimensions in response to temperature fluctuations.

The Science Behind the Motion

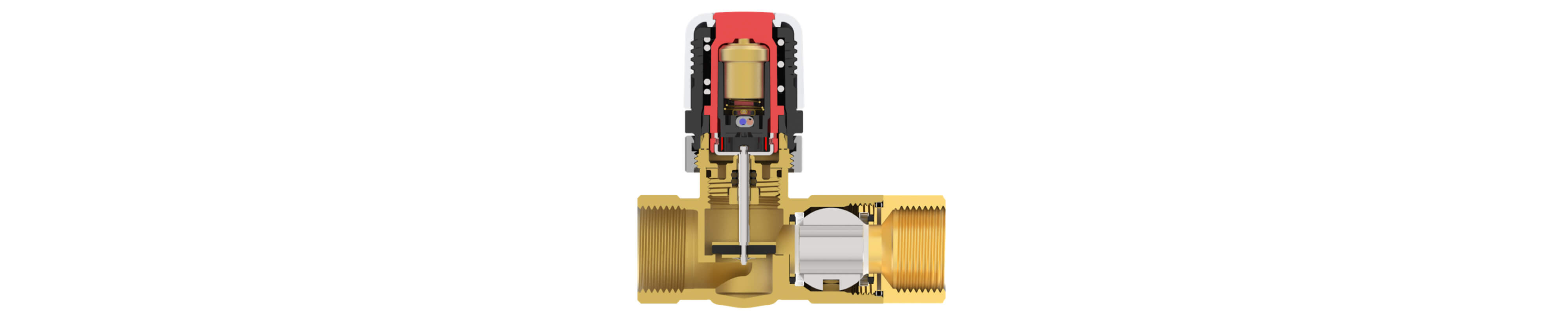

Thermal actuators generally consist of three major components:

Heating Element: Typically a resistor or a bimetallic strip, this element heats up when an electrical current passes through it.

Wax Motor: A specialized substance that expands when heated and contracts upon cooling. This wax is carefully selected for its predictable thermal behavior.

Mechanical Conversion System: This part translates the wax’s expansion and contraction into linear or rotational motion, effectively turning thermal energy into mechanical work.

When the heating element is activated, the wax inside the actuator absorbs the heat and expands. This expansion pushes against a mechanical mechanism—whether it’s moving a valve, opening a door, or adjusting a thermostat. When the heat is removed, the wax cools, contracts, and resets the system for the next cycle.

What Are Thermal Actuators Used For?

What Are Thermal Actuators Used For?Thermal actuators boast a wide array of applications, thanks to their robust and simple design. Their adaptability makes them indispensable in several industries and technologies.

In HVAC systems, thermal actuators are primarily employed to control the flow of air and fluids. They operate valves, dampers, and flaps to ensure that the system maintains a consistent and comfortable temperature. By responding quickly to temperature changes, these actuators adjust the flow dynamically, contributing to energy savings and improved indoor air quality.

Home Appliances and Beyond

A notable example of a thermal actuator in everyday life is its integration into home appliances. Consider the washing machine: a wax motor can be used to control the opening and closing of the door. Here’s how the process unfolds:

· Design and Integration: The actuator is incorporated into the washing machine’s mechanical system, ideally located near the door hinge.

· Activation and Motion: When the user initiates the door-opening sequence, the heating element in the wax motor is activated. The resulting heat causes the wax to expand, thereby generating the force required to open the door.

· Cooling and Reset: Once the door has been opened, the actuator cools down and the wax contracts, resetting the system for future use.

This efficient conversion of thermal energy into mechanical motion underscores the versatility of thermal actuators.

Underfloor Heating Systems

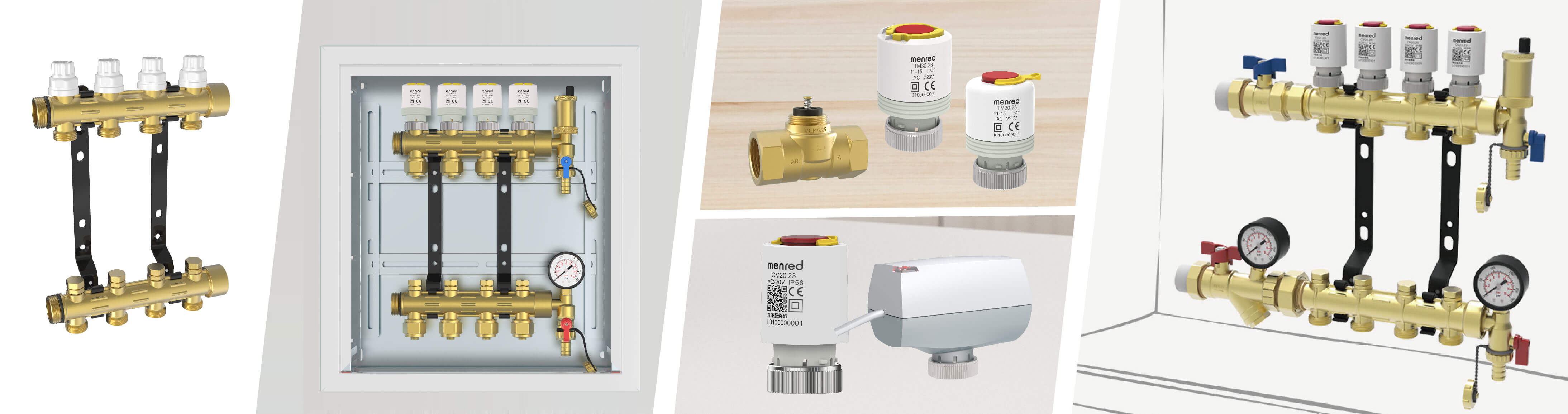

One of the most transformative applications of thermal actuators is in underfloor heating. Modern underfloor heating systems are designed for energy efficiency and precise control over different zones within a building. Thermal actuators enable:

· Individual Room Control: Each zone can have its own actuator, allowing for customized temperature settings that enhance comfort.

· Rapid Response: The quick actuation of valves ensures that each room’s temperature adjusts promptly, maximizing efficiency and reducing energy wastage.

· Silent Operation: Unlike some mechanical systems, thermal actuators operate quietly, preserving the serenity of the living or working space.

How Does a Thermostatic Actuator Work?

How Does a Thermostatic Actuator Work?Thermostatic actuators are a specialized subset of thermal actuators designed specifically for temperature regulation. Their operation is rooted in the same principles of thermal expansion and contraction, but they often include additional control elements for enhanced precision.

1.Heating Initiation:

The process begins when the actuator’s heating element is energized. This element, which may be an electrical resistor or a bimetallic strip, starts to produce heat when an electric current flows through it.

2.Wax Expansion:

The generated heat is transferred to the wax motor contained within the actuator. As the wax heats up, it expands. This expansion is both predictable and controllable, providing the basis for precise mechanical movement.

3.Mechanical Movement Conversion:

The expansion of the wax creates a force that is transmitted to a mechanical linkage—be it a piston, a rotating shaft, or a lever system. This force is harnessed to actuate a specific mechanism such as opening a valve or adjusting a damper.

4.Temperature Feedback Loop:

In a thermostatic actuator, the system is often integrated with a thermostat. The thermostat monitors the ambient temperature and sends feedback to the actuator. When the desired temperature is reached, the actuator’s heating element is deactivated.

5.Cooling and Contraction:

Once the heating element stops, the wax begins to cool. As it cools, the wax contracts, reversing the force generated during expansion. This contraction resets the actuator, preparing it for the next cycle of operation.

The key advantage of thermostatic actuators lies in their ability to provide fine-tuned control over temperature-sensitive processes. Whether regulating the water flow in underfloor heating systems or controlling airflow in HVAC installations, these actuators offer unmatched accuracy. Their reliability is enhanced by a minimalistic design that reduces wear and tear over repeated cycles, ensuring consistent performance over long periods.

Integrating thermal actuators into underfloor heating systems offers numerous benefits that extend beyond mere temperature regulation. Here are some of the standout advantages:

1. Individual Zone Control

Underfloor heating systems typically cover multiple rooms or zones. With thermal actuators, each zone can be individually controlled. This granular level of management ensures that different areas of a building can be heated according to their specific needs. For instance, a rarely used guest room can have its heating minimized, while living spaces maintain optimal warmth.

2. Fast and Responsive Temperature Adjustments

Thermal actuators are celebrated for their rapid response times. When a thermostat detects a change in room temperature, the actuator quickly opens or closes the valve to adjust the water flow. This swift action prevents temperature fluctuations and maintains a consistent, comfortable environment.

3. Energy Efficiency and Cost Savings

The precise control offered by thermal actuators ensures that energy is used only where it is needed. By optimizing water flow in different zones based on real-time temperature readings, underfloor heating systems can significantly reduce energy consumption. This efficiency not only contributes to lower utility bills but also supports environmentally friendly practices.

4. Silent and Low-Maintenance Operation

Unlike some mechanical systems that generate noise or require frequent maintenance, thermal actuators operate almost silently. Their design—with few moving parts—minimizes the risk of mechanical failures and reduces the need for regular maintenance. This reliability is especially valuable in residential settings where noise and upkeep disruptions are major concerns.

5. Seamless Integration with Smart Home Systems

Modern thermal actuators are designed to work in tandem with both wired and wireless control systems. This compatibility enables seamless integration with smart home technology, allowing homeowners to control underfloor heating systems via mobile apps or voice commands. The result is a highly automated, user-friendly heating solution that caters to the demands of modern living.

Beyond underfloor heating, the advancements in thermal actuator technology are driving innovations across the entire HVAC sector. By offering rapid, precise, and energy-efficient control, these actuators are transforming the way modern heating and cooling systems are designed and operated. The result is a new era of smart, adaptive climate control systems that meet the demands of increasingly complex architectural environments.