Comprehensive Guide to Fresh Air ERV Systems: Dehumidification, Humidification, and Air Quality Control

views: 4143 time: 2024-07-04

views: 4143 time: 2024-07-04

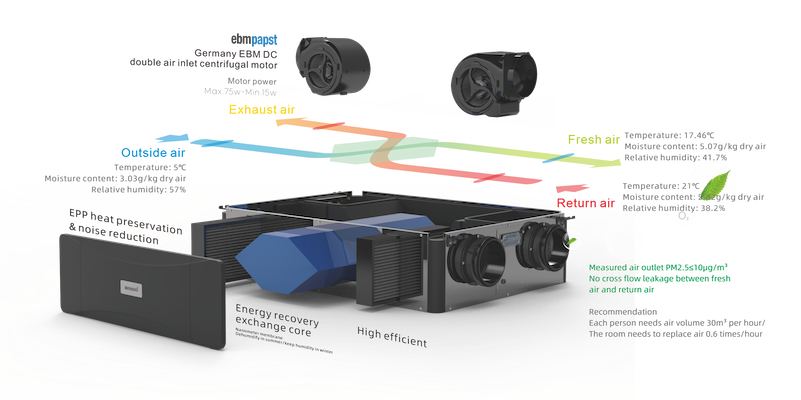

There is a certain relationship between supply air temperature and humidity in the fresh air energy recovery ventilation(ERV) system, which can be understood through empirical data.

Using "temperature of 25 degrees, humidity content of 10g/kg(air), enthalpy value of 50 kJ/kg" as a reference,

- For every 1-degree change in temperature, the enthalpy value changes by 1 kJ/kg.

- For every 1 gram/kg change in humidity content, the enthalpy value changes by 2.5 kJ/kg.

Please note, these are empirical data and not applicable for design calculations.

Cooling Dehumidification: Lowering air temperature by 2.5 degrees can remove 1 gram/kg of water. Ensure insulation of ducts to prevent condensation, or achieve isothermal dehumidification through reheating.

Isothermal Humidification: First raising air temperature by 2.5 degrees, then adding 1 gram/kg of gaseous water. Otherwise, even with added moisture, it may not reach the desired room.

Many friends ask "why install fresh air ventilator”? First, let's analyze the sources of indoor pollutants, mainly kitchens, bathrooms, and human bodies, which are the main sources of indoor air pollution. Pollutants can be divided into physical particles, chemical gases, and biological bacteria.

1. Filtering physical pollutants from outdoor air, such as PM2.5, cotton fluff, and pollen.

2. Diluting the concentration of indoor chemical pollutants, such as TVOC, formaldehyde, and carbon dioxide, and reduce them to levels that are safe and healthy values.

3. Inhibiting or blocking the propagation of biological pollutants in the air, such as bacteria and viruses.

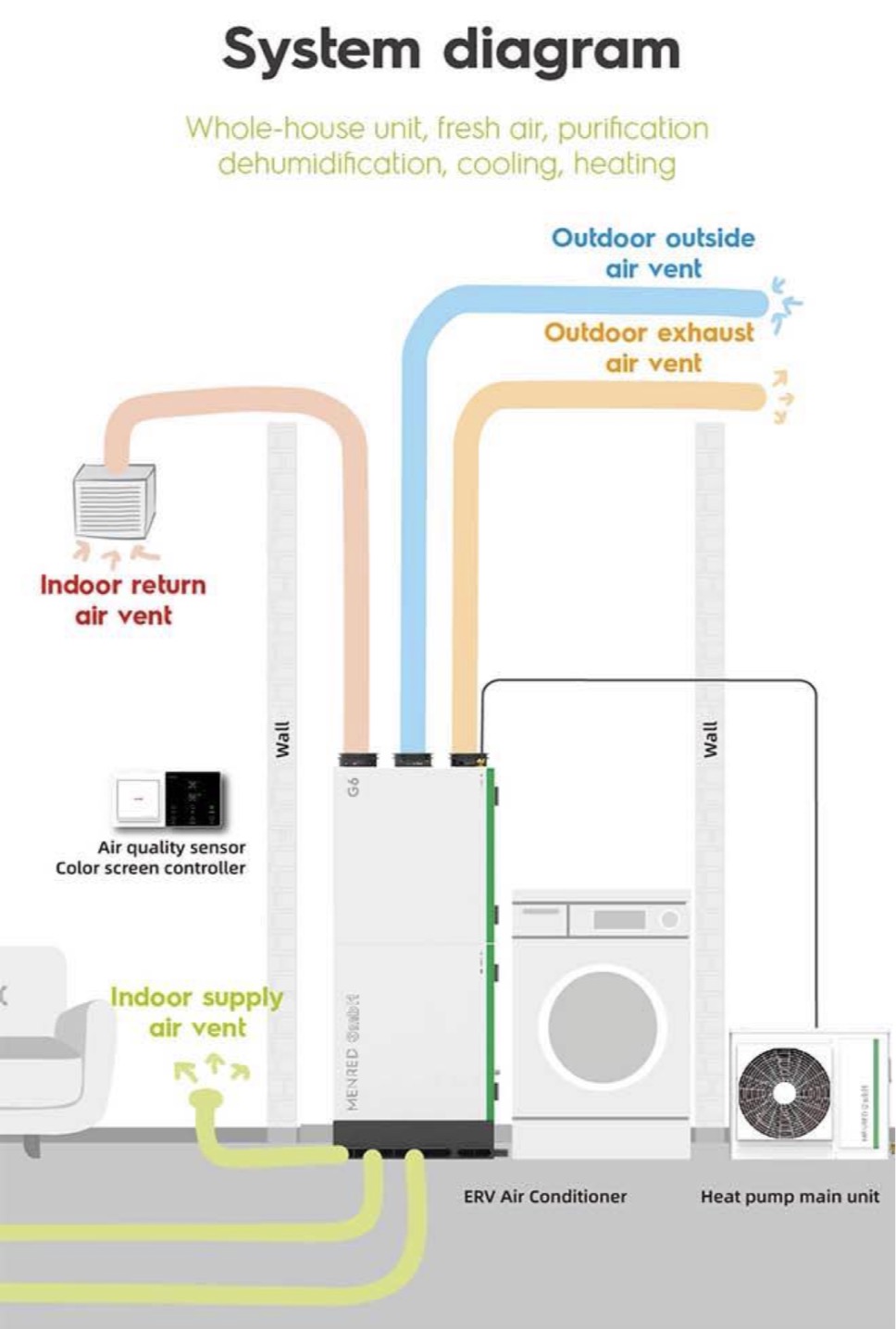

In the Five Constant Systems, the fresh air ERV system, also known as "fresh air air conditioning," not only serves the above functions but also undertakes dehumidification, humidification, humidity control, and temperature regulation tasks.

1. Generation of moisture: Liquid water is transformed into gaseous water using technologies such as electric heating, electrode, ultrasound, and pure water vaporization.

2. Addition of moisture: Typically achieved using heating coils to raise air temperature above 30 degrees to ensure effective moisture addition.

3. Transportation of moisture: Insulating ducts and maintaining appropriate air temperatures facilitate long-distance transport; otherwise, humidified air may condense into water droplets when encountering cold duct walls.

4. Retention of moisture: In winter, with relatively high indoor humidity and moisture production, heat and moisture recovery and exchange technologies help maintain indoor humidity.

1. Summer cooling dehumidification: Enhanced dehumidification with 4-row coil, internal circulation, temperature reduction dehumidification.

2. Summer cooling dehumidification: Enhanced module with 6-row coil, combined with heat and moisture recovery fresh air, dehumidification capacity of 45 kg/day, PTC reheating for temperature control.

3. Year-round pre-cooling dehumidification: Dual-source dehumidifier with built-in inverter compressor; 500m³/h airflow per hour, dehumidification capacity of 50 kg/day, temperature increase dehumidification.

4. Year-round heat and humidity dehumidification: Heat and humidity exchange core + built-in inverter compressor, fresh air replacement dehumidification; dehumidification capacity of 108 kg/day, isothermal dehumidification.

5. Year-round temperature control dehumidification: G6 fresh air air conditioning + outdoor compressor fresh air replacement dehumidification; suitable for basements, dehumidification capacity: 108 kg/day.

Classified by installation method into ceiling-mounted and floor-mounted; classified by air treatment into full air circulation and full fresh air replacement; classified by seasonal use into summer-type and year-round-type.

Summer-type: Uses heat pump to produce chilled water for direct cooling dehumidification. Advantages include simple and stable system with low cost, but it can only perform dehumidification when the heat pump cooling is activated in summer.

Year-round type: Includes independent small compressors, with options for water coil or heat and humidity exchange pre-cooling dehumidification, capable of pre-dehumidification in summer and humidity retention in winter; compressors can be internal or external.

Integrated system combining dehumidification, humidification, fresh air, purification, heating/cooling, and total heat recovery,

Full-range sensing control, monitorable via smartphone app cloud platform. It has the following six capabilities:

- Dehumidification: DC inverter compressor for deep dehumidification, fresh air outlet humidity content always ≤ 8g/kg;

- Humidification: Requires external RO pure water machine, humidification rate of 4 kg per hour.

- Fresh air: Dual full DC EC inverter fans, airflow options of 500 or 1000 cubic meters per hour.

- Purification: Multiple PM2.5 filters, UV and plasma sterilization.

- Heating/Cooling: Supply air temperature 16-24°C, automatically adjusts based on seasonal strategies of "isothermal, cooling, heating.”

- Efficiency: Heat and moisture exchange, enthalpy exchange efficiency ≥ 65%; pre-dehumidification with eight drainage trays and deep dehumidification with three fluorine trays.